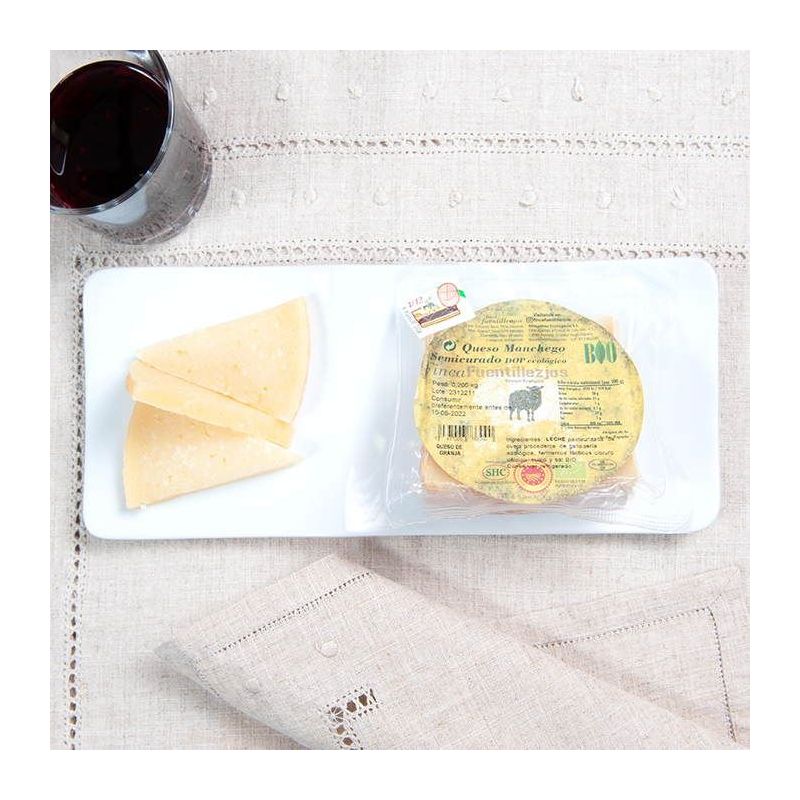

The process of how cheese is made is a fascinating combination of science and culinary art. From Manchego cheese to other fresh or aged spanish cheeses, cheese making involves a series of steps that transform milk into a gastronomic delight.

In this article, we will delve into the cheese-making process, exploring each stage of its production to understand how the variety of flavors and textures we enjoy are achieved.

Initial Steps in How Cheese is Made

The process of how cheese is made begins with a series of essential steps that lay the groundwork for the variety and quality of the final product.

These initial steps are crucial in cheese making, as each decision and technique used directly affects the characteristics of the cheese, such as its flavor, texture, and aroma. Below, we will detail these initial steps in the process of how cheese is made, emphasizing the importance of each stage.

1. Selection and Preparation of Milk: It all starts with the selection of milk, which is the raw material for cheese. Milk can come from different sources: cow, goat, sheep, among others. The quality of the milk is crucial; it must be fresh and of high quality, as it will significantly influence the flavor and texture of the cheese. In some cases, raw milk is used to preserve natural flavors, while in others, pasteurized milk is preferred for food safety reasons.

2. Pasteurization: Pasteurization is a process by which milk is heated to a specific temperature for a set time and then rapidly cooled. This process is fundamental in how cheese is made, as it eliminates pathogenic bacteria and stabilizes the milk, which is especially important if the cheese is to be consumed by people with weakened immune systems. However, some artisanal cheeses are made with raw milk to maintain certain flavors and characteristics.

3. Acidification: Lactic acid bacteria cultures are added to the milk to begin the acidification process. These bacteria convert the milk sugars into lactic acid, which changes the structure of the milk proteins. The type of bacterial culture used and the duration of acidification will affect the flavor and texture of the cheese.

4. Coagulation: Rennet is added to the acidified milk to coagulate it, meaning the milk transitions from a liquid state to a gel or solid mass, forming curds. Rennet can be of animal, vegetable, or even microbial origin. The firmness and size of the curds also play a crucial role in the texture of the cheese.

These initial steps in how cheese is made are crucial in establishing the quality and character of the final product. Each type of cheese requires a specific combination of these elements, demonstrating the rich diversity and complexity of the cheese world.

Cheese Making Process: Curding and Molding

The cheese-making process enters a crucial phase with the formation of the curd and its subsequent molding.

These steps are decisive in the texture, shape, and, to a large extent, the final flavor of Spanish cheese. The skill and techniques employed at this stage reflect the artisanal mastery of the cheese dairy and are essential in defining the type and quality of cheese. Below, we will detail the process of how cheese is made, focusing on the curding and molding stages.

1. Cutting the Curd: After the milk has curdled, the next step in the process of how cheese is made is cutting the curd. The size at which it is cut has a significant impact on the amount of whey released and thus on the cheese’s moisture content. Larger curds retain more moisture and result in softer cheeses, while smaller curds produce firmer, drier cheeses.

2. Cooking and Washing the Curd: In many types of cheese, the curd is cooked at a specific temperature, which helps to harden it and expel more whey. This step is crucial in the cheese-making process, especially for varieties like Parmesan or Gruyère. In some cases, the curd is washed, reducing its acidity and resulting in a softer, sweeter cheese, as in the case of Gouda cheese.

3. Molding and Pressing the Curd: The curd is placed in molds that shape the cheese. The pressure applied during pressing expels the remaining whey and compacts the curd, defining the cheese’s texture. The pressing time and pressure vary depending on the type of cheese being made. Cheeses like Cheddar require firmer pressing, while cheeses like Brie are barely pressed.

4. Draining: Draining is the process of removing excess whey from the curd. This step is fundamental in how cheese is made to determine the cheese’s final consistency, as higher moisture content produces a softer cheese, while lower moisture content results in a harder cheese.

The process of how cheese is made, from curd formation to molding and pressing, is an art that requires precision and care. Each step and decision made during this cheese-making process influence the cheese’s unique characteristics, from its texture and firmness to its maturation capability and flavor development.

Final Steps in How Cheese is Made

Maturation is a fundamental stage in the process of how cheese is made, marking the difference between a basic product and one with developed and complex flavors and textures.

This final phase in cheese production involves a series of specific care and conditions that allow the cheese to develop its unique character. Below, we will detail the last two steps in the cheese maturation process, where patience and expertise are key to obtaining an exceptional quality product.

Cheese Salting

Salting is an essential step in cheese maturation. It can be done directly by applying dry salt to the cheese’s surface or through brine baths. Salt not only enhances the cheese’s flavor but also acts as a natural preservative and aids in crust formation.

Moreover, salt regulates bacterial activity, which is crucial for flavor profile development and cheese texture during maturation.

Ripening or Maturation: The Final Step in Cheese Making

After salting, the cheese is transferred to cellars or maturation chambers, where it is stored under controlled temperature and humidity conditions. During this period, which can vary from weeks to several years, the cheese develops its characteristic flavor, aroma, and texture.

In this phase, some cheeses may be bathed, brushed, or turned regularly to ensure even maturation. Maturation is a living and dynamic process: bacteria, molds, and enzymes act on the cheese, gradually transforming it.

Maturation time varies greatly depending on the type of cheese; for example, a young Cheddar may mature in a few months, while a Parmesan may require several years to reach its full flavor.

Maturation is undoubtedly one of the most artistic steps in how cheese is made. It is a period where the cheese acquires its identity and distinguishes itself from other products.

This meticulous and carefully controlled cheese-making process is what gives each cheese its distinctive stamp and what makes the cheese dairy a revered culinary art.

Understanding how cheese is made allows us to appreciate this age-old food even more. Each step in cheese making, from milk selection to maturation, is an art that has been perfected over centuries.

Cheese making is a science in itself, full of nuances and details that result in the wide variety of cheeses enjoyed worldwide.